Services

Our manufacturing services are specifically catered to the aerospace, defense, commercial, medical and space industries. Here is a list of our expertise.

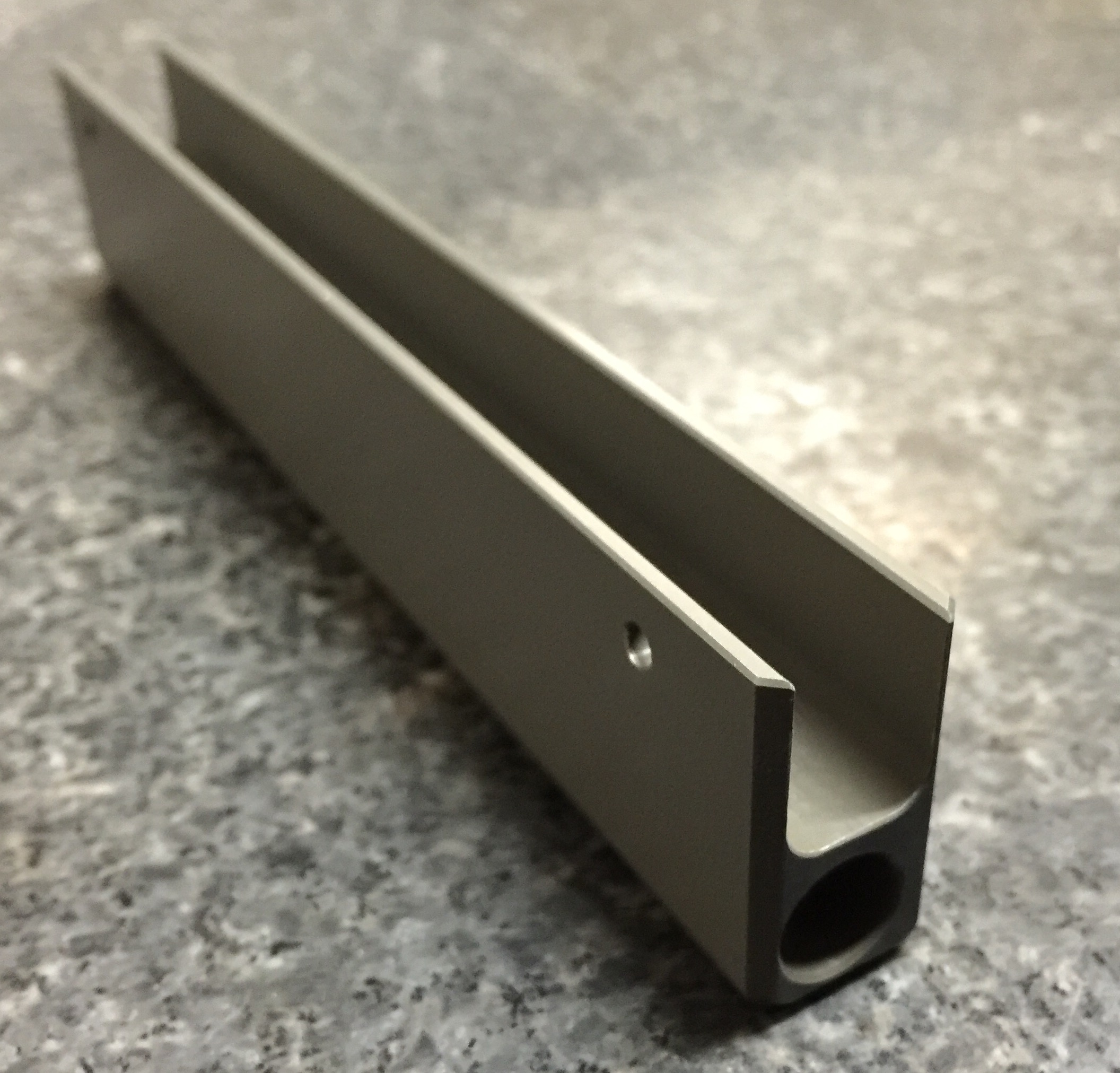

CNC Milling

Our 3-axis, 4-axis, 5-axis milling capabilities allow us to manufacture a diverse range of precision components, whether individual parts or mass production. Multi-axis machining is where TurboTech truly thrives because our milling solutions are a direct result of our programming acumen, proper judgment and ability to solve problems.

CNC Mill-Turning

The integration of milling and turning in one platform gives us and our customers great flexibility. The three key benefits of going the mill-turning route are increased part accuracy, efficiency, and output. The best ways we know how to maximize those benefits are to take advantage of the latest technologies and utilize the most up-to-date methods.

CMM Inspection Service

We put a great deal of effort into ensuring that we remain a trusted source and utilize the latest technologies from FARO and Hexagon CMM. The right inspection technologies help us catch errors and avoid issues. Parts are rigorously inspected before they hit your dock. When we deliver quality, others know that they can count on us.

Material & Saw Cutting

When it comes to material for your next project, rest assured that we’ll get an awesome price on it and transfer those cost savings over to you. We purchase and machine thousands of pounds of metals on a weekly basis. Once the material hits our floor, we establish traceability records and utilize our internal automatic NC saw cutting capability.

Complete & Turnkey

TurboTech Machining understands that our customers want hands-off, complete plug-and-play solutions. We'll make sure that when the product hits your dock, it’s ready for immediate use. We utilize NADCAP approved vendors for all outside processing and have the internal capability to perform assembly services in house.

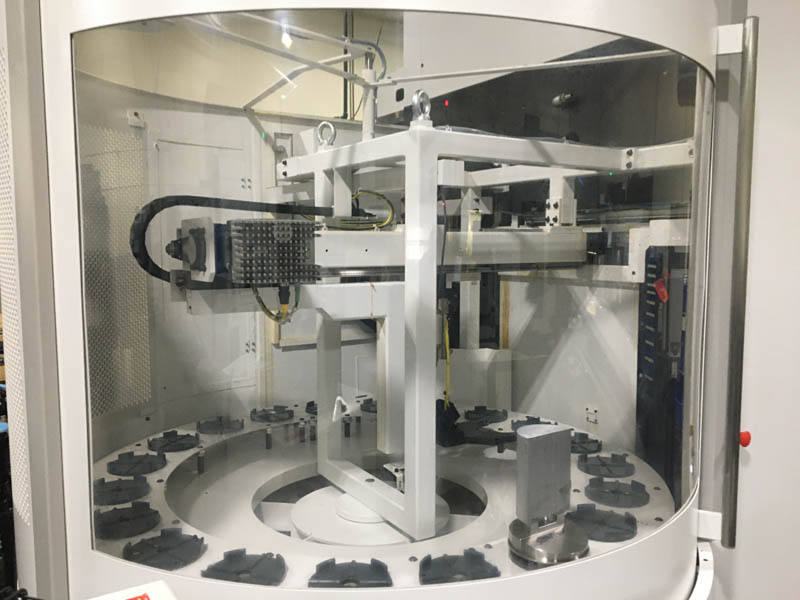

Automation & Robotics

We have the internal capability to complete your projects with automated pallets and robotics. This translates into your projects running 24/7 at the highest efficiencies. We have implemented some of the latest technologies that allow us to have robotics open and close the machine door, pick up blanks and insert them into machine and remove finished parts.